That’s probably way to provocative for my situation, but it does seem I have the engine sorted and it should be fine for a good few years now.

Thursday 7th August. Chiapas, Mexico.

I mentioned the in mast furling failure that happened to a boat that arrived here a few months ago. Well it’s taken a while but the owner returned a few days ago and motored over to the haul out area where a big mobile crane was waiting.

This young lady went up the mast, I presume to fix on some straps for the crane where she took the picture below of the marina. SM is hidden in the far right at the back. The mast furthest away. The blue ketch closest is the Sea Shepherd Research Vessel, Martin Sheen, now on the Atlantic side of Mexico, Great boat/crew doing great work for the oceans.

Not long after, the boat was back on it’s slip, sin mast.

And the mast was on the ground, where it still remains, although they do now seem to have extracted the sail.

Word around the marina is that the crew who helped sail the boat here lacked experience with furling mainsails. Basically the sail is wrapped around a thin tube inside the mast, driven by a motor. When you fire up the motor, the sail needs to be on the right side of the mast and under a bit of tension. If the sail goes slack it can ruffle up inside the mast and jam. This is what the crew may have done. I dread to think how much this is costing the owner, but it’s going to be in the ten’s of thousands of pounds, that’s equivalent to a small terraced house, where I come from.

So on to the engine, hopefully for the last time in a long time.

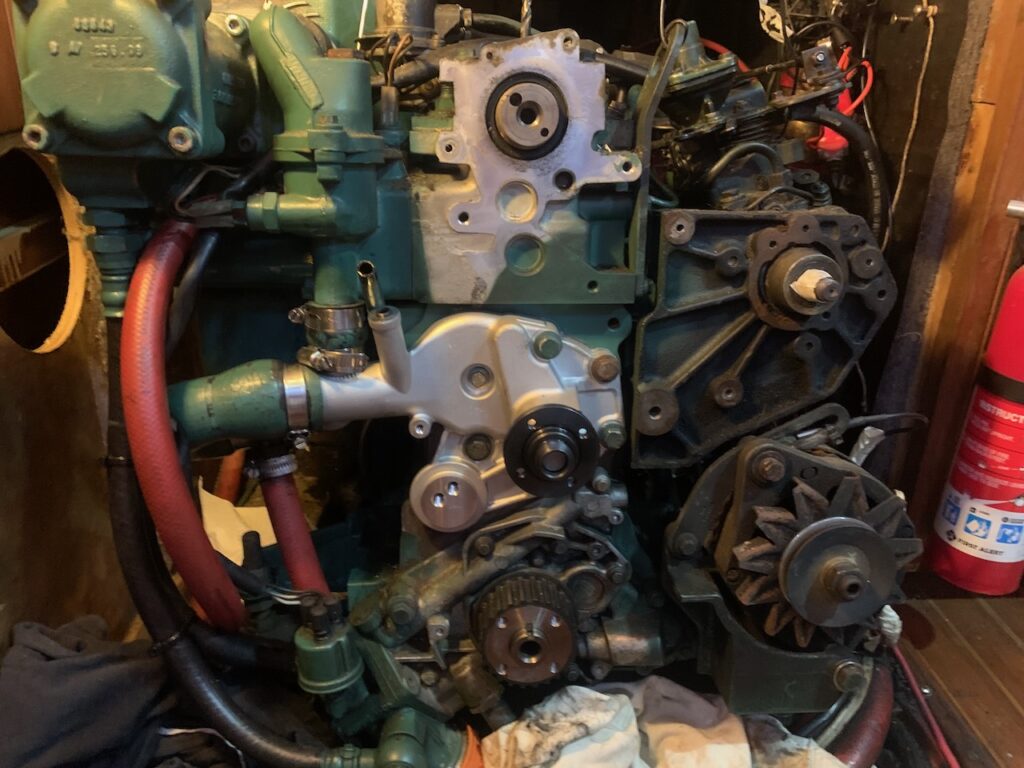

The water pump arrived from England, you can see the old one in the pic below, it’s the small wheel in the middle of all the other cogs and pulleys.

To get to it, tons of stuff has to come off the engine. It’s fairly major and took a whole day.

Just the crankshaft pulley left, this requires a special tool to lock the flywheel, which isnt available anymore, but also would require removing the starter motor, which would be a pain. Thankfully modern technology has come up with an alternative, the Impact Driver, which can sort of undo a nut without turning it. I had to borrow one from Dois, but it made short work of the task.

Above you can see the water pump is off and the way into the engine block is revealed. This was exciting, I was looking inside my engine for the first time.

Here you can see the wall of the combustion chamber (where the piston goes up and down), I’d like to work in the ‘Piston broke’ joke here, but sadly can’t find a way.

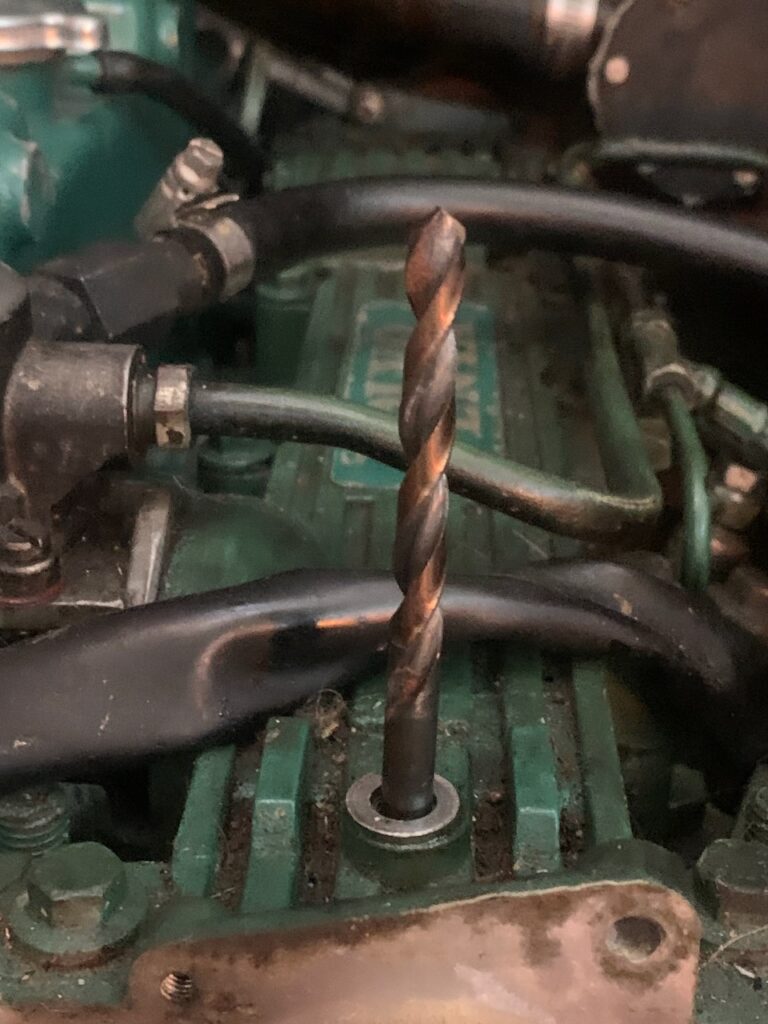

Above you can see the unofficial way to stop the camshaft rotating, you’re meant to buy a 6.75mm diameter ‘drift’ from Volvo, but a 6.5mm drill seems to work just fine. There’s another one stuck through a hole in the flywheel casing to stop the crankshaft moving.

It looks a lot bigger in real life.

Above, the new and old pump

Above some bits that need to go back on. I’m so glad I took pictures, because I couldn’t work out which cog went where.

So with the pump fitted, I got it all back together. One day to take it apart, and another to put it all back. So with some trepidation, I turned the key and …. nothing, Nada.

The start switch on the control panel has been playing up. So I hot wired the starter and Brummmm brummm brum., off she went sounding sweet. No leaks, no gasses into the water tank, water plopping out of the boat exhaust, everything was just fine.

It was now the weekend so time to relax

I pumped up the dinghy and took it out for a ride. The last time I tried the outboard, I had to take the carb off and when I put it back on the max revs seemed low, I took a screwdriver with me this time to adjust the throttle cable settings as I suspected that to be the problem. It turned out to be fine, it was just me getting confused and thinking I had a fast outboard. I may well treat myself to one. This dinghy has never been on a plane (Where it lifts out of the water and rides on its own bow wave), that might be fun.

I went out past the fishing fleet and into the main channel.

Above and below are the remains of a previous fishing fleet. I think there are 4 or 5 sunken boats here. Must have been one heck of a storm.

This is the view heading back to the marina.

So below is the engine control panel. It’s very advanced and touch sensitive. Whenever the oil pressure gets too high, or too low, you just tap the display and it changes, with enough tapping you will eventually get the oil pressure you desire. The same goes for the other dials. Occasionally they need to rest and won’t display anything for a day or two.

We’ve coped with this for ten years, but now it was being quite touch insensitive and wouldnt let me start the engine.

This range of volvo engines has a special diode connecter cable between the engine wiring loom and the panel, with 4 multipin connecters which I guessed were the problem, so I got ruthless and hacked them out. Now the panel is hardwired to the engine. If you want to replace it, tough luck. You can’t get them anyway.

One by one, I snipped the wires and replaced them with a new cable to join them up, I only needed two video calls to Kathy to work out the colours, I’m red green colour blind, thankfully most colour combinations used by volvo were easy for me. However there was one wire I couldn’t work out if it was red, brown, green or what! I was flabergasted when Kathy told be it was red/green striped. That should be the new colour blind test, stuff all those coloured circles, this was impossible to see any stripe on.

It’s far from perfect, but I no longer have a touch sensitive panel. Unfortunately the start switch problem is still there, and appears to be inside the actual key mechanism. That’s easily fixed, I will just put a start button onto the panel.

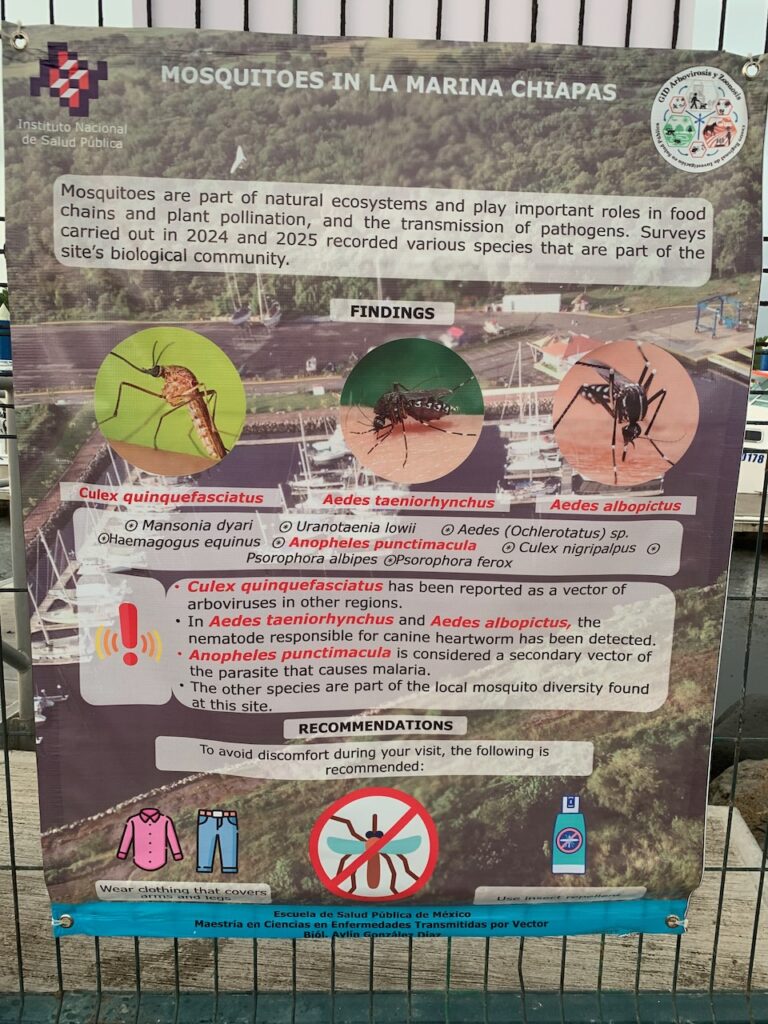

I don’t have any mosquitos on board, but I do get bitten most nights by these invisible buggers.

I had to empty the Lazzerette as part of my engine operations and as I mentioned before had started to replace the hoses that drain the cockpit from rain and any waves that might pop over. I had one pipe out of four left to do as the others had not been blocked. I replaced it, only to find out the blockage was in the sea cock, something the diver had said he would clear for me a few weeks earlier. So I replaced the last pipe and stowed all the above away, well 50% of it went in the bin. Some stuff I bought in Malaysia that had never been used.

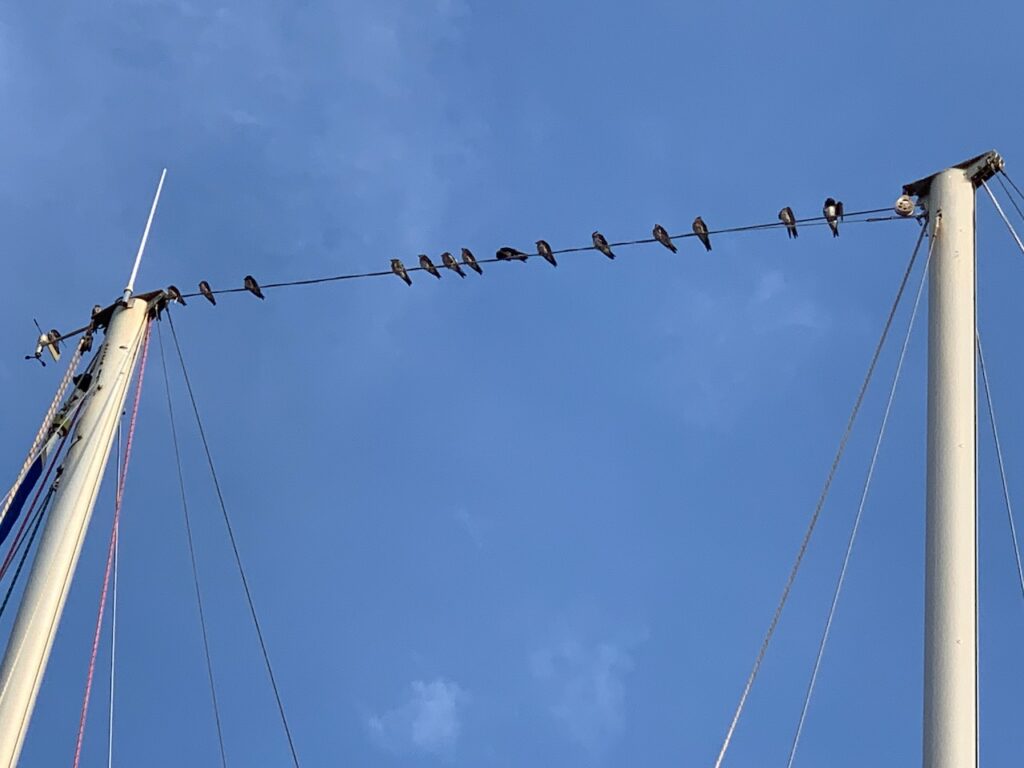

A Hitchcock reminder (The Birds)

Thursday 7th August 2025

So today I undid the dock lines and motored out of the marina to see if the boat still worked and if I still knew how to drive it. It’s been over a year since this prop did any work.

So the minute I started to reverse away from the dock I knew something was wrong, I revved up the engine to generate some prop walk and there wasn’t much at all. Normally I feel the boat kick a bit, then the wind started to blow the bow back towards the dock, a little blast on the bow thruster didn’t do much so I revved her up a lot and slipped away safely, but going the opposite way to how I had planned. I was pretty sure the propellor and/or the hull were fouled, probably barnacles. I wasn’t expecting that as I had just had a diver clean the bottom and prop about a week earlier. I almost returned back to the dock, but I thought I would see how it went. Manoeuvring just really meant I needed a bit more welly on the throttle.

One of the fishing fleet loading its net onboard

Check out the helicopter on the roof and the lookout tower on top of the mast

I got out to the ocean, just past the harbour entrance breakwaters, I planned to head a mile out to sea, maybe put up the sails, but I soon realised the autopilot was just not doing a very good job of steering. So I killed the revs and just bobbed around a bit. I was going to check the temperature of the engine and bits around it with my newfangled ESP32 computers talking to Home Assistant on my raspberry pi. They all talk over the boats wifi, but I had set it up all wrong, and for some reason I don’t yet understand, when my Starlink connection went down, so did the boats wifi. So I didnt even have toys to play with.

Hurricane Ova has just passed by and I think that may have been responsible for the big waves and very rolly conditions. So I didn’t hang around. I headed back to the dock. All in all I was out for about two hours, because of the fouled hull, the engine worked hard, I had her at near max revs for quite some time and the temperature was rock solid on the display.

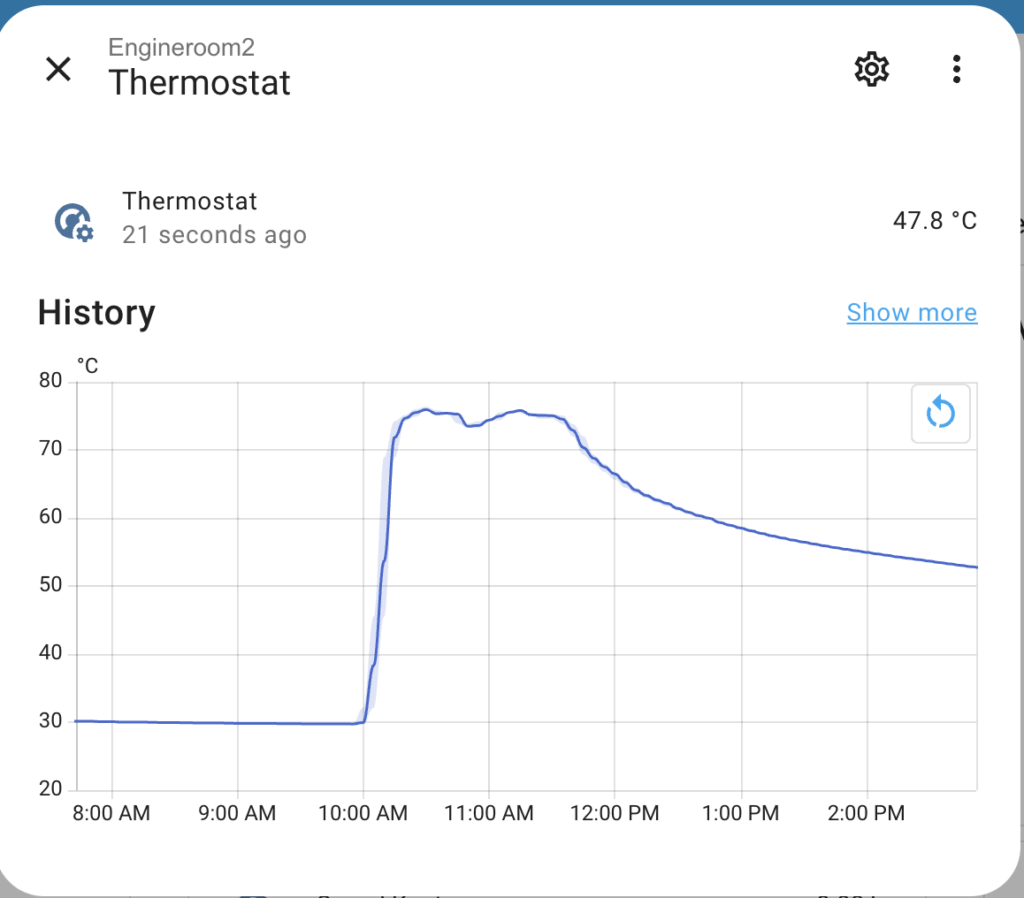

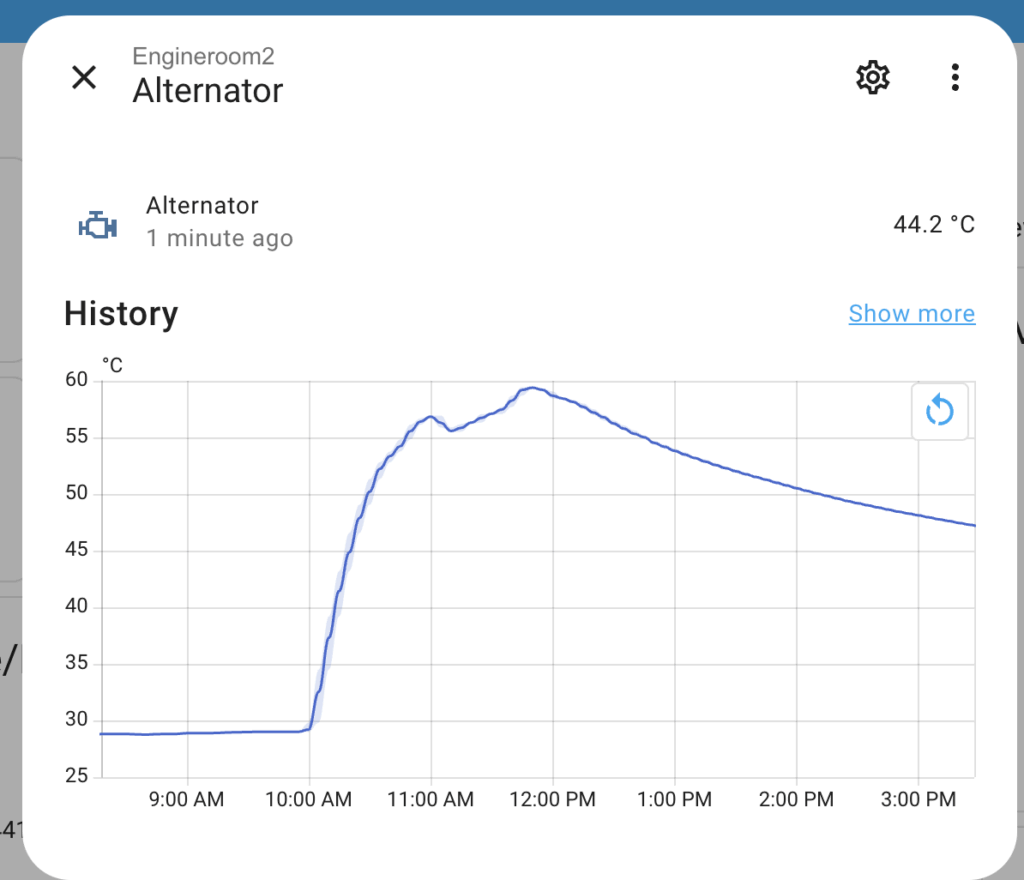

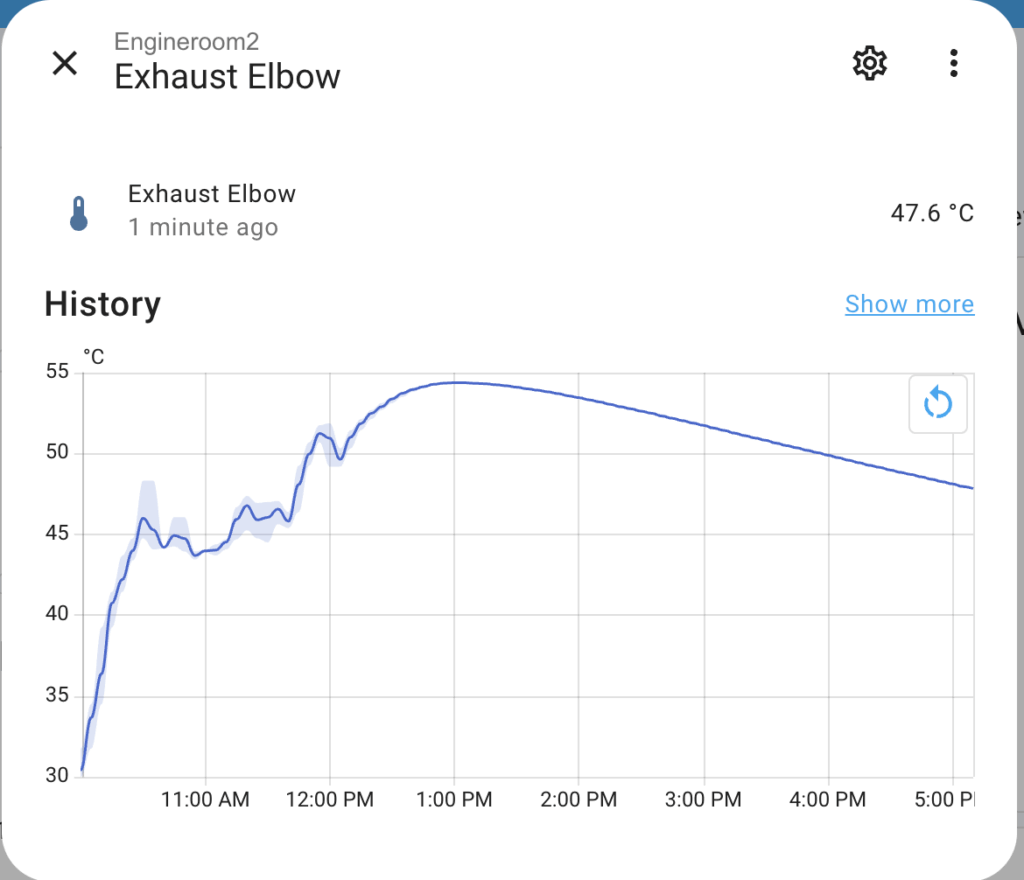

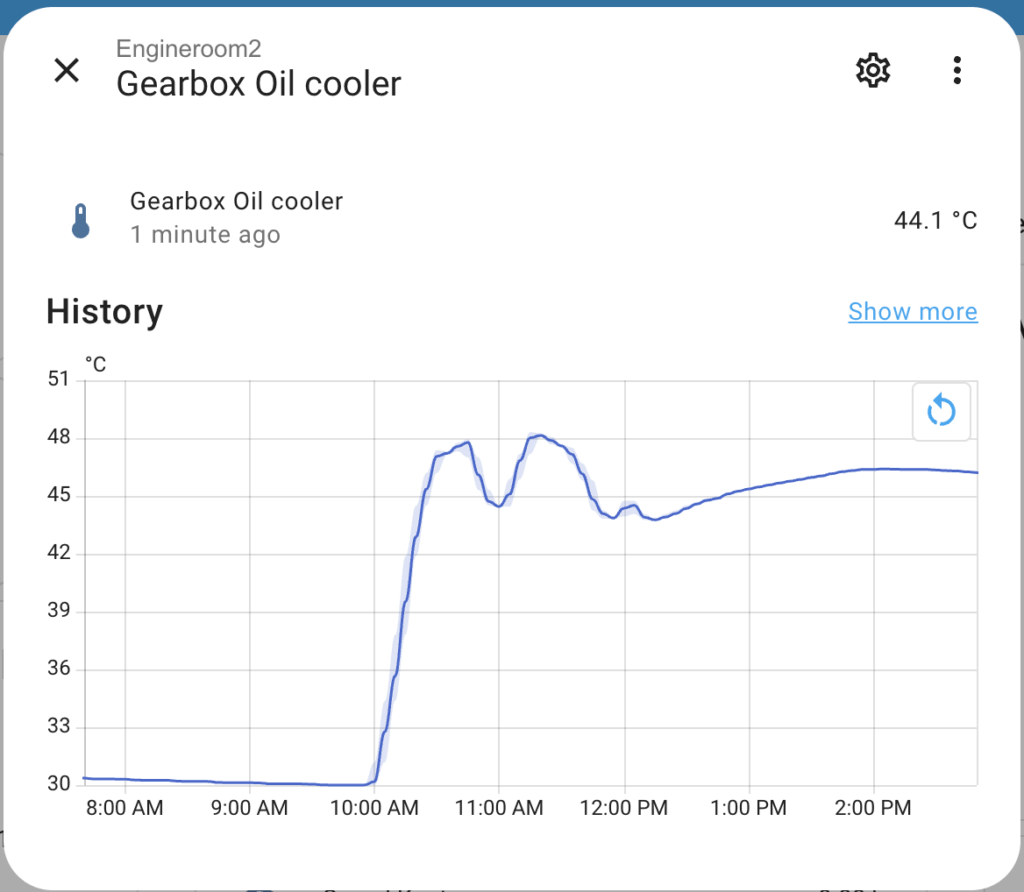

When I got back to the dock I was able to pull some temperature stats of the Pi and they are shown below.

I don’t really know what to make of these numbers yet, but it’s good fun having these four sensors in the engine compartment. I can monitor trends, set alarms and get my AI to do something with them. Endless hours of entertainment.

I’m going to fix the autohelm and wifi, clean the prop and get back out there in a few days. I’d like to get the sails up, it should be calmer next week.

So it’s been a long slog getting this engine back online, but interesting, and educational, not forgetting expensive. I have no excuse now not to get on with making the boat (varnish/paint) look pretty again.

Paul Collister 7th August 2025.

There’s full employment for you in Galway if you ever want 🙂