Tuesday 24th November 2020

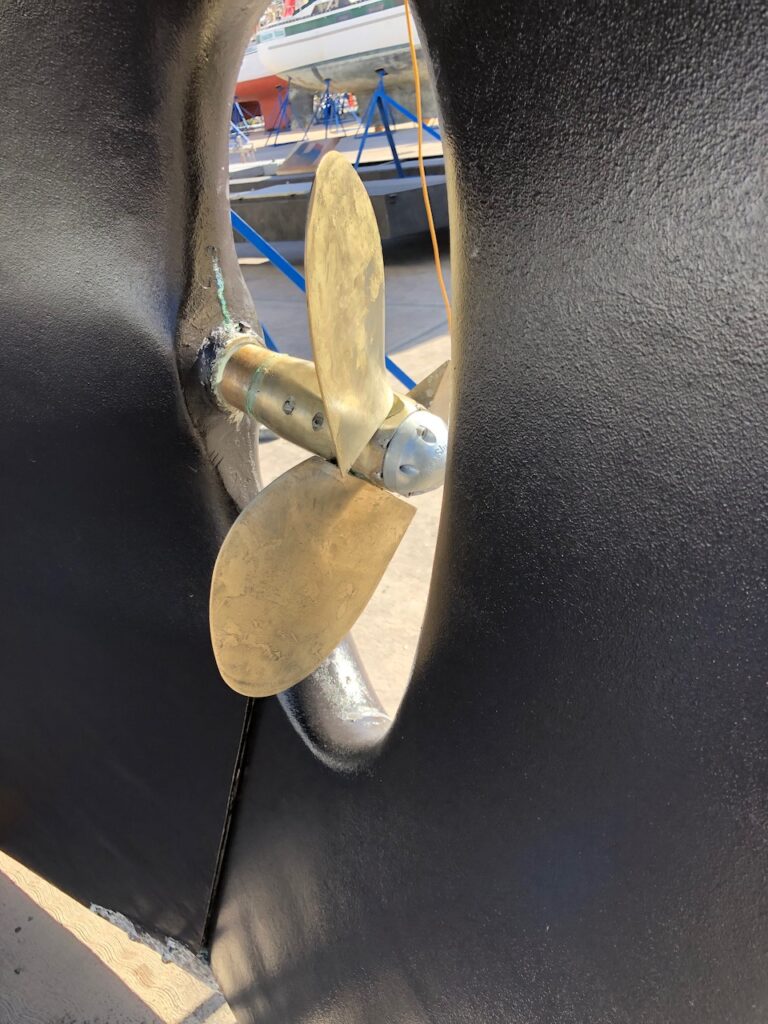

Our first day on the hard, and this is a very hard concrete yard we are in, and it’s not as bad as I was expecting. There’s not a lot going on here other than two men who are sanding the old antifoul off the hull in preparation for 2 coats of new interspeed 640 hard antifouling. I spent the day cleaning the prop, fitting a new anode to it and repairing the autopilot which failed just after we left Agua Verde. Once again the key that holds one of the cogs to the drive shaft fell out. Unlike the last time, I couldn’t find the key. I took this as an opportunity to give that area of the boat, behind the rudder shaft a good cleaning, with the hopeful bonus of finding the key. Thinking about it, I should have found it, and I’m wondering if the key might have slipped back into the motor housing. I ended up having to make a new key, and realising I don’t carry any material I could cut, 5mm by 5mm square, I chose a 10mm stainless steel screw and set about filing it down. It took a little while, but fit perfectly in the end. I made a dimple in it for the set screw that hadn’t done its job before and all was well, except I couldn’t test it as a lad was busy below sanding the rudder. I checked it before bed and it seems to be working fine. Later I heard Gerry and Chris, the two boats we met in Agua Verde calling for help with their lines as they approached the marina. I wandered down to the pontoon to help. A useful tip I picked up on my travels around is to have some ropes and fenders ready for when you dock, also it’s best to try to be parallel (ish) to the dock when approaching, it’s much harder when you are 90 deg to it 😉 . It was good to see them safely tied up. Later Kathy and I enjoyed a meal at the smart restaurant upstairs, Kathy was delighted to see a decent vegan menu on offer.

By the end of the day, 1/4 of the hull had been sanded, and several very small blisters had been decapitated. Back in Penang, Malaysia, nearly 5 years ago, there were several hundred blisters, many the size of saucers, the hull treatment seems to have worked well.

Costs:

As I was looking at the quotes for the haul out and paint job, which aren’t small, I thought I might pen a few notes on the cost of cruising for us. This seems to be a popular thing on other blogs, so without too much detail:

Monthly costs in the dock: £600 (Typical in the sea of cortez for a 45ft slip)

(Includes electricity, water, facilities, etc, just add food & drink)

Haulout & relaunch cost: £370

Labour to sand and paint hull, (2 guys 5 days ish) £1200

Paint: 3 gallons (11.5 litres) £600

Total haulout & paint job (£2170)

So I would do the haulout every two years normally, this time it’s over three since I painted. So that averages about £1000/year. And £600/month for the slip seems a lot, but because we are at sea/anchor a lot, it probably averages down to £500/month over a year. My costs of running the apartment back on Merseyside wasn’t that much less, when I consider Service charges (£120), Electric/Gas(£100), Council Tax (£110). Food and drink is cheaper here, I sold my home in West Kirby last year, so fortunately I don’t have those bills anymore. So all in all it’s not costing us much to be spending our time hanging out in exotic, tropical paradises as you might think.

Of course there are big ticket items that come up every now and then like new sails every 5-10 years (£5000), new standing rigging (Wires to hold up the mast) every 10 years, (£4000), failing electronics, probably a few hundred pounds every year. At some point I will need a new engine, that could be anywhere between £5000 and £15,000 depending on who does the work.

The other big cost we have is flying home from far flung places.

Wednesday.

The sanding continues, fortunately it’s not too loud inside the boat, but later a second guy joins and it’s getting a bit noisy. I book a hire car in the marina office so we can spend tomorrow being tourists, and get Kathy to a big supermarket before her shopping withdrawal symptoms kick in. I rub down the propellor, it has no grease in it at all, which is fair enough I suppose. I last serviced it in Sointula nearly two years ago. I spend the day doing some programming for work, it goes remarkably well, and I produce a flash user interface, well flash by my usual standards of 80×24 character, 128 levels of grey! Aren’t plugins great.

The sanding is taking forever.

Thursday

After a half hour of waiting for the car I go to the office to find out the lady there forgot to book it for me. Oh well, Manaña.

The sanding is continuing, It looks like they will complete today. They are doing a great job, but it’s going to be 6 man days work, I’m sure in Kudat, Malaysia it took one guy three days. I decide to have a serious go at bow thruster anodes, the props are badly fouled on the inside and impossible to clean without removal. I have tried several times to take the anodes off on past haulouts, but the bolt that holds them in place wont budge. The zinc has corroded around it, plus I think the wrong loctite may have been used on them, until I remove the anodes, I can’t get to the holding nut. Generally the anodes have not changed much in the 5 years they have been on, which in itself is an issue. I have a problem as all my 5mm allen keys needed for these bolts are missing, I think they broke on various jobs, I have one that I have filed down to be a 4.5mm ish key for some odd job in the past. I give up with the one key I find as it just isn’t budging and the key is two long to put across the prop. The shopping list for tomorrow grows. I also need to try and find anodes for the stern of the boat.

Friday.

Hurrah the rental car arrives at 9AM and we load up and head into town, I stop at an auto-service parts place and pick up an expensive allen key set, that comes with a snazzy ratchet wrench for about £15. The same or similar tool was available in Mr Tool, in Malaysia for no more than £5. Anything that is imported here, even value Chinese goods is pricey. I wonder if this is how the UK will be next year, A GoPro for £300 will cost £400 due to taxes & shipping fees. Next off to the Chandlers, where they have no suitable zinc anodes, I also can’t find any drill bits that I could use to fashion a block of zinc I have into the part I need for the stern.

I show Kathy around town, This is my third trip here and I’m almost a local. The wind blows very strong, but we find a lovely spot for lunch in the town square. I will let Kathy write about that, so far she has fared well for Vegan meals, largely thanks to the ingredients in Guacamole being quite veggie.

Off to the supermarkets (note the plural) and I am pleased to be able to stock up on cases of soda and cerveza sin alcohol. Kathy even finds some vegan products in the Ley Supermercado. From the town, we head up into the mountains to visit the mission at San Javier. This is a very old mission, in a valley right up high in the mountains, 30 km from Loreto and very remote. It shows what faith those missionaries must have had, it takes us an hour in a car on a tarmacked road to get there, goodness knows how long it must have taken back in the 17th Century with dirt tracks and donkeys. Kathy is surprised to see this little oasis of a village appear out of the mountains with the mission at the end. It is quite a lovely spot. I’m sure Kathy will elaborate.

Back at the boat I can see they have finished the sanding, but no painting has started yet.

Saturday

Painting begins, but not before I crawl under the boat and get my head under the keel, I can see there’s a large chunk of it missing. I’m guessing it’s from when we hit the mis-chartered rock in Canada, looking at it in detail, I’m thinking the hull material in the area looks messy, I’m wondering if in the past it has been patched up badly. I organise for it to be filled, glassed over and finished with epoxy resin.

Also the strip of damage near the rudder is filled ready for fairing.

I watch a YouTube video from Sidepower, the people who made my bow thruster, about removing the anodes then the prop, but the anode bit seems to have been edited out. It’s not a lot of use, a guy has a bow thruster on the table and he holds the propellor on one side as he undoes the nut on the other. I scroll down to the comments where some guy has written “Thanks for that, but unfortunately I have a boat wrapped around the bow thruster, so your technique doesn’t work.”. Thankfully the reply suggests showing a block of wood through the prop to hold it in place, something I had thought of doing but was worried it would damage the prop. As it turns out this works fine, and the allen keys I bought allows me to remove the anodes, and then the props.

Funnily enough, when I dig out the new anodes from my expensive/tiny boat bits locker, I find two 5mm allen keys in there, I obviously thought at some point in the past, this would be a good place to keep them. Forgetting that I always forget such great ideas. I clean and paint the props and will refit them tomorrow.

Next I try to drill holes in a large zinc block I have that could replace the wasted zinc on the stern. I always thought you had to drill slowly with metals for best effect, it seems with Zinc it’s better to go like a madman with the fastest drill you can, ignore the smoke and glowing drill bit, just go for it. I am making a big hole with lots of smaller holes, and the only way I can justify the result is that you have to dive under the boat to be able to see what a terrible mess I’ve made of it. In fact I may wait until just before launch to fit it so the boatyard staff don’t laugh at me. As the sun sets we head up to the restaurant here and have a lovely dinner.

Sunday

The boatyard is quiet today, so I clean the prop and then fill it with marine grease.

I finish off hacking a hole in the zinc anode for the stern and fit it. It’s a terrible bodge, but it will work. I expect as the zinc wears away, the nut will come loose and it will vibrate itself to bits. My plan is to replace it and the other one on the port side with the correct anodes when I get back to La Paz, they may be in stock there, if not I can order them. Hopefully I can dive and replace them myself with my new scuba skills. Tomorrow was meant to be launch day, but I think it will need to go back to Tuesday, also we have quite strong northerly winds at the moment, so my plan to go north won’t work right now.

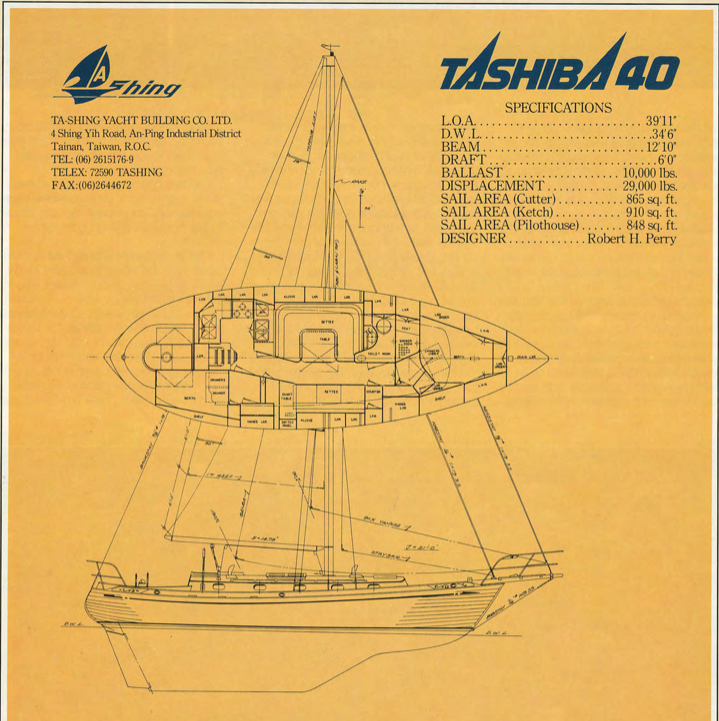

I did a little more checking on the boat weight today, as the ton/tonnes thing always confuses me. The boat weighed 17.5 metric tons in the travel lift slings.

That’s the same as 38,581 lb. Looking in the sales brochure for the boat, the weight (displacement) is stated as 29,000 lb, making us 10,000 lb overweight.

Or 30% overweight. That seems a lot, the problem is that manufacturers always want to play down the weight for sales reasons, lighter boats go faster. So they often leave off things like anchors & chain, fuel and water, cookers, batteries, even the mast sometimes, anything that might be optional. Even so, I think we might be a touch too heavy. Kathy suggested we could lose some books, but I expect she means my books 😉

Monday

The boat bottom has been painted with two coats in most places, there’s more to do, but the final bits will be done in the morning when the boat is in the slings.

The rudder bit has been repaired, it’s not perfect, and the bash to the keel looks fine now, and at least it is solid and no water could work its way into the ballast.

The bow thruster props cleaned up well, I have painted them with the antifoul used on the hull, I’m not sure how well it will work, it was a bit thick going on, but I expect it will soon ablate off.

Tomorrow we launch, into the tail end of a strong northerly, typically we are heading north, against the wind which I expect will be gone by the time we turn for the south. We will explore the islands around Loreto. I’m looking forward to having a faster boat again. The bow thruster let us down on the way into the travel lift, I noticed the control panel LEDs went dim when it was engaged, this might have been because of the growth on the props, but I suspect it is more likely going to be an electrical problem. This could be one of two obvious things, a bad connection, which would be great as that’s an easy fix, but more likely, the batteries can’t supply the many hundreds of amps needed to turn the prop. Tomorrow if the prob is still there I will be running around the boat with my multimeter while Kathy energises the thruster!

Paul Collister.