It’s the 24th of May and a lot has happened in the 4 weeks since I last posted. The main thing being that I will probably be in the UK by the time you read this, my plane leaves tomorrow. But first, let’s go back to 4 weeks ago when I was getting ready to buy a new engine.

28th April

I had decided to take my time removing the exhaust manifold. I ordered some shiny bolt extractors on amazon.

I was worried that the reluctant bolt was less likely to come out due to the fact that I had removed the tension from the surrounding ones. So out came my torque wrench. I’ve never used one of these before, not even sure why I have carried this fine shiny example around the world with me, but I read up on the tensions, only to find contradictory advice, it was either 22 or 38 thingies tight. I translated the manual from Chinese and worked out how to set the thing up and set it to the lower one 22 I think, I started to torque the bolt and it tightened very easily, Some of you might have guessed the next bit already, Tightened some more, and some more, then Crack, the bolt snapped, I had over tightened it and snapped it off somewhere inside the manifold or engine head. Just shows how well, good fitting sockets can work. At this point I felt terrible. I shouldn’t be let loose near the big tools, and once again I called it a day knowing my intervention had made things worse.

One thing I find fascinating is how many birds are here, and how they are constantly nest making at the moment.

Every day I try to walk a mile or two around the yard and along the river. In the boat yard the birds are busy building nests in the most incredible ways.

May 3rd

Eventually the special sockets for removing rounded nuts arrived, I tried them but found it was difficult to get a good swing at the socket with the hammer given there’s only a few inches between the nut and the bulkhead (wall). I thought I might have it on but no, it just spun. Now I have a round nut with a spiral groove.

I chatted with Dois about my failings and we agreed that I need to cut a hole in the bulkhead, buy some socket extensions, and whack it on hard. Dois lent me the hole cutting attachments and I was about to go and cut the hole when he asked if I had talked with Dave. Dave who I asked, Dave the engine expert on the white yacht opposite. Dois had been helped out by Dave and I think the deal was that Dois had to keep quiet about Dave’s mechanical skills, he hadn’t come to Chiapas to spend all his time fixing other peoples boats. The thought of an English speaking mechanic in the marina was almost too much for me. Dois took me over and apologised for spreading the word, but Dave was great and agreed to come and look right away.

Dave agreed that I should get some extensions for the sockets and a big hammer, cut a hole, and he told me about a teqnique of using a ring spanner on the socket and a big wrench on the extension to keep the forces straight. I needed more kit so we agreed to meet up later at the site of a big hole in a bulkhead where lots of shiny new tools would await a hammering.

Feeling quite optimistic, I jumped on the collectivo into town the next morning at 8am. Home Depot had everything and I spent a lot of money on sockets, extensions, reverse out drills and so on. The trip back on the Collectivo was something else. I had no idea these mini busses could go so fast, around corners it felt like we were only using two wheels.

The coconuts are in season now and the gardeners who tend to the marina leave piles of them at the foot of the trees which we are able to help ourselves too.

This time of year is brilliant for fresh fruit, and with the coconut, bananas and mangoes, one can feast away on produce growing within the marina grounds.

The Gasket and some seals arrived from the UK, they flew through customs, without any issue.

I drilled the hole through the bulkhead, it’s not going to be visible to anyone and worked out really well. I loved the hole cutters, going to be getting some for the boat.

However when I checked out the sockets I had bought and the extensions, they were all 1/2″ I need 3/8″ I hadn’t realised that there were different sizes, and I was surprised to find out that even though the world had gone metric, with just one country holding out, that we still used imperial for the extensions and backend of the socket. Anyway, the next morning I rushed back into town, and exchanged everything for the correct size. Back at the boat I got everything ready for Dave the engineer to come over and supervise.

Dave arrived and in no time at all fitted the special extractor, hammered it on, got the spanners turning and the bolt came out. I was over the moon, couldn’t thank him enough. Like all good engineers he took a keen interest in the problem and offered to remove all the nuts and help me get the whole manifold out. This was great, as I’m sure there was still potential for me to mess something else up.

With the manifold out, I finally have access to the rusty area by the gearbox. Dave’s view was that the engine looked in amazing shape and he thought it would be mad to replace it if I could replace the manifold.

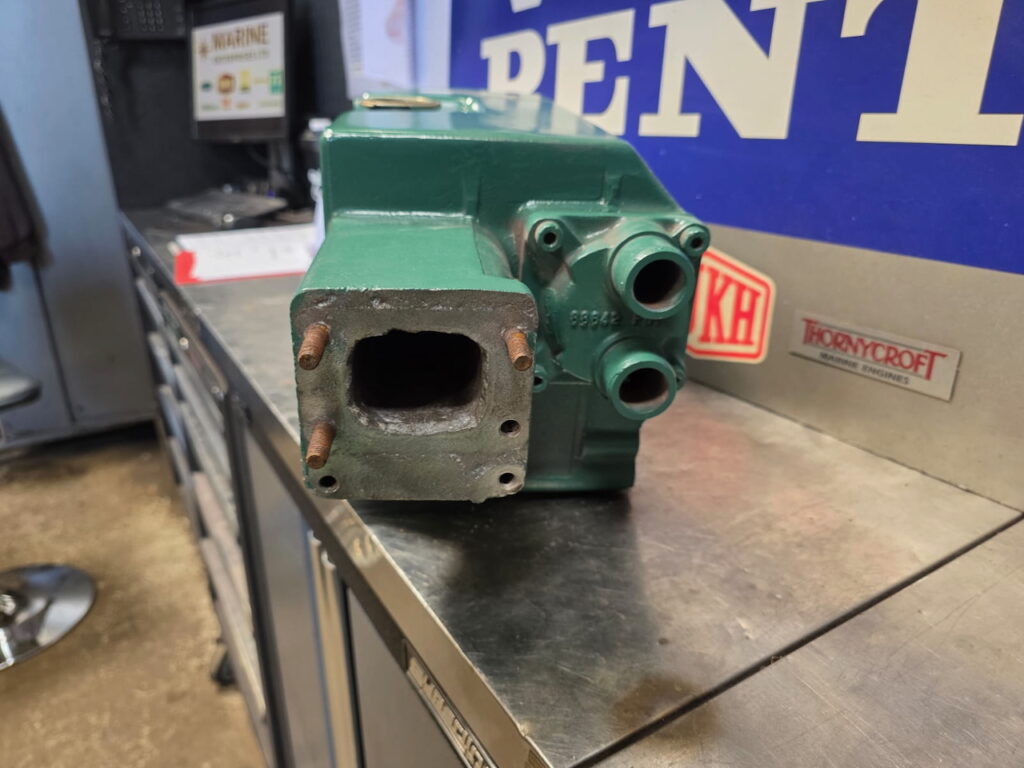

Once out of engine compartment, Dave spotted the problem right away, there was a hold in the jacket/wall of the manifold.

Below you can see the hole, the smaller one on the right.

Once I cleaned it up, gently with a wire brush, the extent of the damage was obvious.

In the picture below you can see how much material has been lost, I put some card into the exhaust outlet to show the original wall of the outlet and just how bad it was now. Later Mario the engineer told me he could see about getting it welded up, and took it to a welder, who said for £500 he could do a good repair. Dave had previously said it was beyond repair and I shouldn’t even try. I also know from obsessive youtube engineering repair videos I’m addicted to, that you can’t really weld to Cast Iron, you should braze, and that would be a lot of brazing.

I had found a scrap engine dealer in the uk who had a manifold of the correct type, he sent the pictures below and it looked in good condition and the corrosion was claimed to be less than it looked, but it looked way better than what I had , and would probably give another 5 years of service, maybe more if I do a fresh water flush of the exhaust each year. The problem was he wanted an arm and a leg for it, I explained it made more sense for me to go for a new engine, and he offered to sell it for just the arm and from the knee down. So I agreed.

He packaged the manifold up and handed it over to DHL for the 5 day trip to Mexico

I could relax now, there was a plan, and it was in motion, plan b was to get the old one welded up, and plan c , a new engine.

Walking back to the boat I couldnt believe the little buggers had built a nest on my topping lift halyard. They must have worked fast, I’m sure it wasnt there a couple of days ago.

Now I’ve been here before when I was stuck in Mazatlan for weeks because of a nest on the top of the mast, only to see the egg smashed onto the deck when a storm blew through, and although it freed me to leave, the storm kept the port closed and me in port for another week. I didn’t want to lose another 3 weeks here, especially as the hurricane season was rapidly approaching.

I climbed up the mast, got close to the nest, there was no mother around, so I guessed no egg either, looking into the nest, I couldn’t see any eggs so got out a knife and cut the nest down. I felt really bad about this, but thought it better to do it now than once an egg is laid.

I did find smashed egg over the foredeck the next day, so I wondered if the mini storm we had a couple of nights earlier had been responsible, it was all a bit odd.

Even out in the jungle here, you can’t get away from industry. Just a mile away from the marina is a big coffee processing plant. The state of Chiapas is famous around the world for its coffee, and commands a good price, however behind all the fancy marketing, it comes down to processing plants like this one that churn out steam, smoke and coffee dust 24/7. The boats needs constant washing down from a brownish dust that gathers every few days. I believe they process organic beans and general coffee, also they supply Starbucks with their coffee I have been told.

The coffee factory is just behind the docks where the cruise ships land their tourists, keen to see the Aztec and Mayan ruins here. However just a little further along are the prawn ladies. Not that they look at all like prawns, but they sell them along the dock perimeter, and very tasty they are too.

Below is a lovely steel boat, I presume in need of a hard working and wealthy new owner.

This boat below arrived a few days ago and if you look closely you might spot that the mainsail, instead of being rolled up neatly inside the mast is actually lashed to it, rather well I must say. But this must be the nightmare for anyone with in-mast furling. You can only get to Chiapas by doing a long several day overnight passage, so this is the last thing you want to have to deal with. Now in harbour, they are waiting for a mast rigger to come out, and take the top of the mast off to access the mechanics of the system.

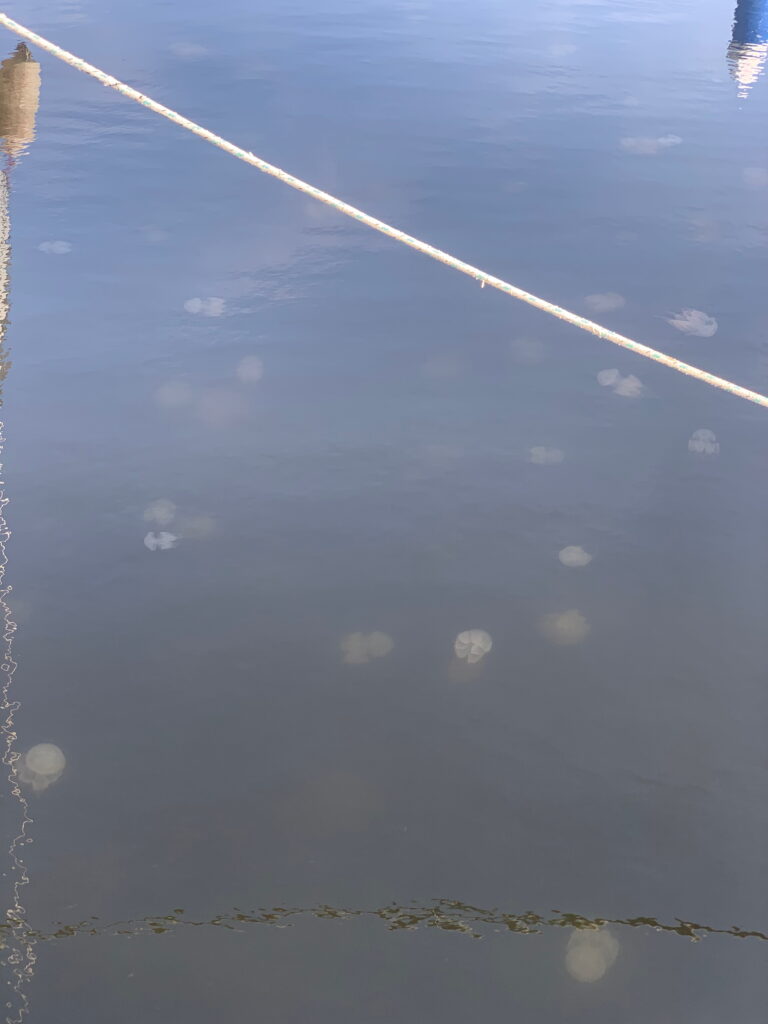

Temperatures are on the up and up, I suspect this may be why so many jellyfish have shown up.

Along with the new manifold I also ordered a new exhaust elbow and some exhaust hose from parts4engines. Now one of the problems you face in Mexico is customs. I know many boaters who have had their goods impounded by customs. They head off to a warehouse in Mexico city and never leave, often the best you can do is hope they get returned to the sender. Now the carrier is ‘muy importante’ here. Fedex and Ups have less success, but DHL have a good record, so I paid extra to have goods sent with DHL. Imagine my feeling to get a note from Parts4engines that my parcel had successfully left their warehouse with Fedex. This was the start of a slightly stressful process. I managed to get the parcel redirected to DHL, but it still ended up in the customs depot in Mexico city. However DHL quickly appointed an import agent and for $30 it was on its way to me with an extra days delay. The big manifold did not fare so well and ended up with a DHL agent who didn’t seem to care much about me getting my package, he didnt read my emails and led me to believe my parcel was on its way back to the UK. Thankfully DHL intervened and just a few days ago I got notice my parcel had cleared customs, I had to pay about 40% of the value in taxes and charges, so that was the rest of my leg added back on, along with half another arm I’d say.

My Exhaust manifold has now arrived in Tapachula, but seems stuck in their depot. I expect it will turn up any day soon.

In the mean time some personal business has required me to return home to the UK. I’m jumping on a flight back tomorrow and expect to be in the UK for around three weeks, the first week in London, then a fortnight back with Kathy in Liverpool. What this means for our cruising plans for the rest of the year, I have no idea. As I speak, there is a tropical depression developing just off the coast here. We are a couple of weeks into the hurricane season now. Hurricanes are usually born here near Chiapas as tropical depressions and then head of up to the north west strengthening on the way, rarely do they turn around and come back here and do harm, but they have, with devastating consequences.

Hopefully when I get back in a few weeks I can bolt the engine back together and if I’m feeling brave, scoot up to Barra de Navidad as planned, but it might just be easier to sit out hurricane season here.

Cheers,

Paul Collister 24th May 2025