Sunday 21st Feb 2021.

So I guess you worked out this isn’t a post from Kathy. It’s a week now since she left and I have started on the task of making the boat look like new. I’m leaving in two weeks as my monthly term with the marina runs out, and it’s time to find warmer water.

Since Kathy left I have been doing small jobs on the boat, a little bit of programming, and quite a bit of lazing around. I’ve tried to up the Spanish learning a bit, but haven’t fully immersed myself as planned. But I’m optimistic I’m going to learn a lot over the next few months.

Arturo is learning the art of varnishing, today he spent two hours stripping old varnish off the eyebrow and grabrails on the coachroof port side. I have asked him to be here for 8am tomorrow so that he can get the first coat of varnish on. I have managed to get a first coat on the rub rails and two coats on the cap rails. I spent an hour today cleaning the steel bars that run along the rub rails to give them extra protection. In all the port side of the boat is starting to look great. With two weeks left I plan to spend one week on the port side, then flip the boat and repeat on the other side.

Arturo unknowingly guided the CEO of an airline (French I believe) around the islands a few months back, he did the whole thing in French, and the owner of the company was so impressed he recommended that a group of his employees use Arturo as their guide when they visit La Paz, so yesterday Arturo led them around the islands listening to him tell them the history of the islands, the story of Hernan Cortez, the mating habits of Sea Lions, and some nonsense on cloud types I taught him. It all went very well, and hopefully Arturo is building up a following and reputation here. I expect he will be running his own high end Eco tour company in a few years time.

Maria has now taken to flying into the cabin and wandering around when I’m not paying attention. Not just to the breadboard, but the length of the boat!

While working on the deck I decided to pour the contents of a diesel jug into the main tank, and then get it refilled at the local station. This will save me taking the boat to another marina to refill. However after I had put about 5 litres of the fuel into the tank I stopped as the diesel looked odd.

I took a sample into a cup and it was definitely the wrong colour, it also smelt of paint. This was worrying, after an hour the fuel looked the same, often a contamination will separate out and sink or float. looking at the container it was stored in, it’s clear the inside is a different colour where the diesel was. I have concluded that the diesel dissolved the inside of the container over time, it may have been in there for a year by now, and that it was so fine it had bound to the diesel fuel like a stain. I disposed of the fuel and the container, I just hope that the fuel I put into the tank isn’t going to be a problem.

I had to do some cleaning in the bilge area of the main cabin and I’m always shocked when I see how much machinary, wiring and plumbing there is. Is this normal, looks more like I would expect on the Space station than in a sailboat.

Another job I finally got started was the starboard whisker stay fitting. This is a bracket that attaches one end of the whisker stay to the boat, the other end goes to the bowsprit, its job is to stop the bowsprit swinging from side to side as the headsail fills with wind, and to some extent when the mast pulls on it.

It had a crack in it, and I have been meaning to do something about it for years, but dreaded taking it off as I suspected it would be very difficult to do. In the end, it took me all of ten minutes. Now I need to find a welder to make me a new one, I had thought it could be repaired, but I think a new backplate is in order.

It’s amazing how stuff like steel can just crack, I doubt this was ever under any real strain.

Monday 22nd Feb

A trip to the optician starts the week off, I wonder if this might be a good way to get the coronavirus and almost back out, but I double up on the masks and take a risk. My eyes are really struggling to read small stuff, and I’m getting headaches if I’m on the laptop for too long. The visit goes well, and they are very diligent in cleaning all the equipment just before I stick my head in it. The poor guy who died in the boat near to us is suspected to have caught the virus from his dentist, but I think they have to get a lot closer than opticians.

The rest of the week is mostly about sanding and varnishing. Arturo is quite handy with a heat gun and scraper now. In trying to find a new scraper I empty out one of the lockers and decide a good clearout is called for. I have a theory if you have done 10,000 miles through countless countries, over several years and you still haven’t used the 7/16″ 6 inch PVC tube, or the vacuum cleaner extension pipe, then they can go. The lockers are a lot more empty, tomorrow I will need a 7/16″ 6 inch PVC tube.

We pop over to a local stainless steel fabricator who is happy to build me a new whisker stay bracket for $2500 (peso), around £90, not cheap, but not outrageous either.

While resting in the cockpit in between coats of varnish, this guy flies in and takes up a sentry position on the monitor steering, and doesn’t seem to care about Arturo and I sitting right next to him. Arturo wonders if it might be one of the local ‘tropical cormorants’ that are around here. It’s quite a big bird and I’m glad Maria and Carlos aren’t here.

By thursday I have slapped about 5 coats of varnish on the port cap rail, and the same amount on the rub-rail. The eyebrow and grab rail also have 3 coats and more will go on, possible once I leave town. The port hull is washed, but not yet polished.

At 3:30, when the tide is turning we leave the slip and head out for a 5 min trip into the bay, long enough for me to move the lines and fenders over to the other side as when we head back into the marina I reverse into our slip so the starboard side is now against the pontoon and we can start cleaning that up.

I take advantage of the engine being hot to change the oil & filter, It’s been 170 hours of engine running since the last change. I think the manual recommends every 100 hours. I wondered if I have recently changed it, but the log I keep says it was last march, a year ago, so that would be about right. I wonder if I forgot to put an entry in the log and as I’m writing this I realise I havent put today’s oil change into the log. So who knows. What I do know is that I aligned the level of new oil exactly to the max oil marker, then I remembered you have to push really hard to get the dipstick to go all the way in, which it did, now I have about 3mm too much on the dipstick. I don’t want to have to extract it, so I need to search the web until I find someone who says it’s ok.

One of the advantages of being ‘Stern In’ is that I get a clearer view of the sunsets from the cockpit, and tonight is spectacular.

The new bracket arrived on Friday and Arturo helped me fit it, I tried to teach him the art of sikaflexing without getting it everywhere, but ended up showing him how to remove sikaflex from unwanted places.

This is one of the things I enjoy a lot about the cruising lifestyle, having to find local trades folk who can make fancy things from basic materials, at short notice, and for reasonable prices. When something like a steel bracket breaks, or a plumbing fitting that’s a bit bespoke fails, just grab said part, head off down the pontoon asking along the way, and you’re soon enough in a workshop with an engineer saying, yes of course I can make that, come back tomorrow.

Next on the list was a leaking deck prism, these are blocks of glass in the shape of a prism, fitted into the deck and when the sun shines, they spread light far and wide inside the boat. I love them, except that they require a large hole cutting in the deck to sit in. This invariable leaks, as this Port/Midship one did.

Unfortunately, as I dug out the old sealant, and criticised the poor workmanship of whoever put it in, I started to recognise the flaws in the fitting. I think the rubbish job, may well have been mine from a few years ago. I decided it couldn’t have been, and proceeded to do the same sort of repair I would have done back then if it had of been me, which means it’s going to leak again. To make matters worse I have decided to rebel against all thing ‘Marine’ that are very similar to non Marine things, like glue and sealant. So I’m using an off the shelf builders sealant at £3 a tube, instead of the fancy Sikaflex at more like £20. I might not be so cavalier if the job was below the water line, but worst case scenario here is that Kathy will get drips on her head if it rains a lot!

Arturo is here every other day or so when there is no work on the tour boats. He is getting better at varnishing and is very good at scraping and sanding. We now have 3 coats of varnish on all the woodwork, with 7 coats on the cap rails. The boats looking a lot smarter. I polished all the steel in the pulpit area, and the bowsprit and platform are looking good.

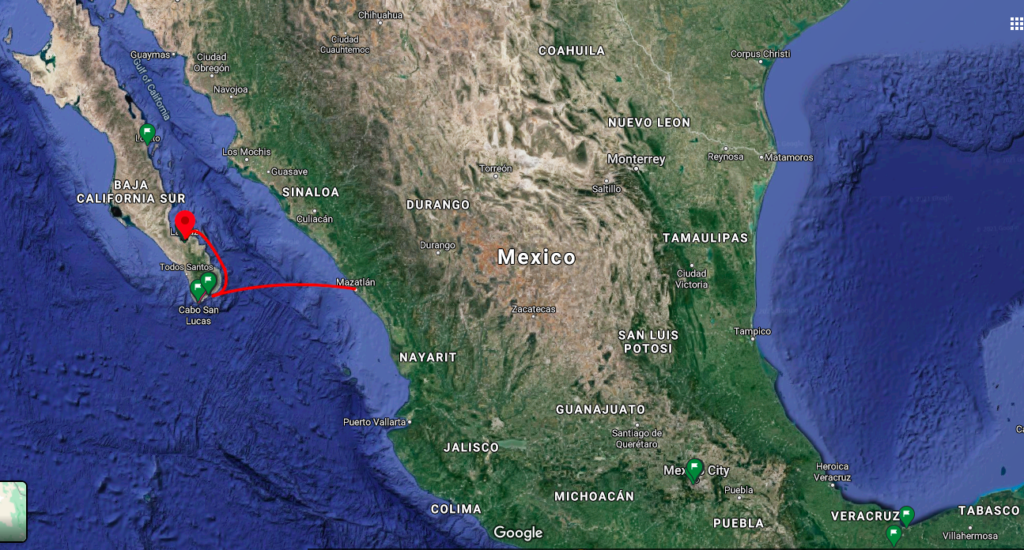

In 7 days time I will chug on out of the Marina, still not sure of where to go, but the most likely destination is Mazatlan over on the mainland, a sail of around 36 hours, So I would leave at 7 AM and arrive in the afternoon on the following day.

Paul Collister