Having arrived at a safe place close to the big cities of Osaka and Kobe, I decided to take on the engine repair. Based on the fact that if (or more likely when) I mess up, I can call in the professionals.

The job required the removal of the fuel injector, and trying to figure out why exhaust gasses and fuel were leaking out from it.

In order to remove the injector, I first had to remove the high pressure fuel return lines from all the injectors, so I could get those pipes out of the way. This was easy, the supply pipe for the bad injector was next. A few other bits of engine came off to help with acesss, then I could try to pull the injector out.

I expected this to be difficult, and when I tried, it was just completely seized in, I guess this was to be expected, carbon buildup on the inside is normal. I believe there is a tool to help pull these injectors, but there was little chance of me getting hold of one. I visited a local hardware store to see if I could build something, but I couldnt find a bolt with the right thread to screw into the injector, so gave up. I put the whole thing back together and thought if nothing else I might have learnt how to remove the high pressure lines. Amazingly the engine still worked, and I couldnt see any fuel leaks. So nothing was lost.

Chatting with the locals here at the sailing club, one member with experience of engines came along to help the next day. I stripped it all down again and he had a go at removing the injector, he couldn’t extract it, but did manage to rotate it a degree or two. I had assumed the injector was keyed and so didn’t try to rotate it. I’m very conscious that an injector is a very high precision device and I’m worried about damaging it in any way by using too much force on it. However after the engineer gave up, I continuing to wiggle it back and forth whilst applying liberal amounts of WD40, eventually it paid off and the injector pooped out.

Here you can see the copper washer close up, there is a chunk missing, perhaps 0.5mm deep which I hoped was the cause of the problem. A trip to the local hardware store failed to find anything close to the right size so I need to order the correct replacement.  In the meantime I carefully sanded down the washer to make it flat again.

In the meantime I carefully sanded down the washer to make it flat again.

My problem with this approach was that both sides are not parallel now, something I have had problems with going right back to my first days in woodwork and metalwork at school. I tried to smooth down the higher side, but knew I was on a looser as that would give me a round side, so I got it as close as I could and hoped that the compression that would be applied would flatten it out. I annealed the washer, this should make it more malleable.

I reassembled it all, after a lot of meticulous cleaning of the injector socket, not at all sure if it would work, but it started first time, with no need for bleeding, and the horrible noise that I had before of the gas escaping had gone. The engine was sounding much better, but closer inspection revealed a small amount of gas still escaping from the injector. the seat that the injector sits in looked like it could do with a polish, but it’s very difficult to access. At least I know how to dismantle it all now, and hopefully when I get the new washer I can try that, however I may get a mechanic in when I reach America/Canada and get that and a few other jobs done on the engine.

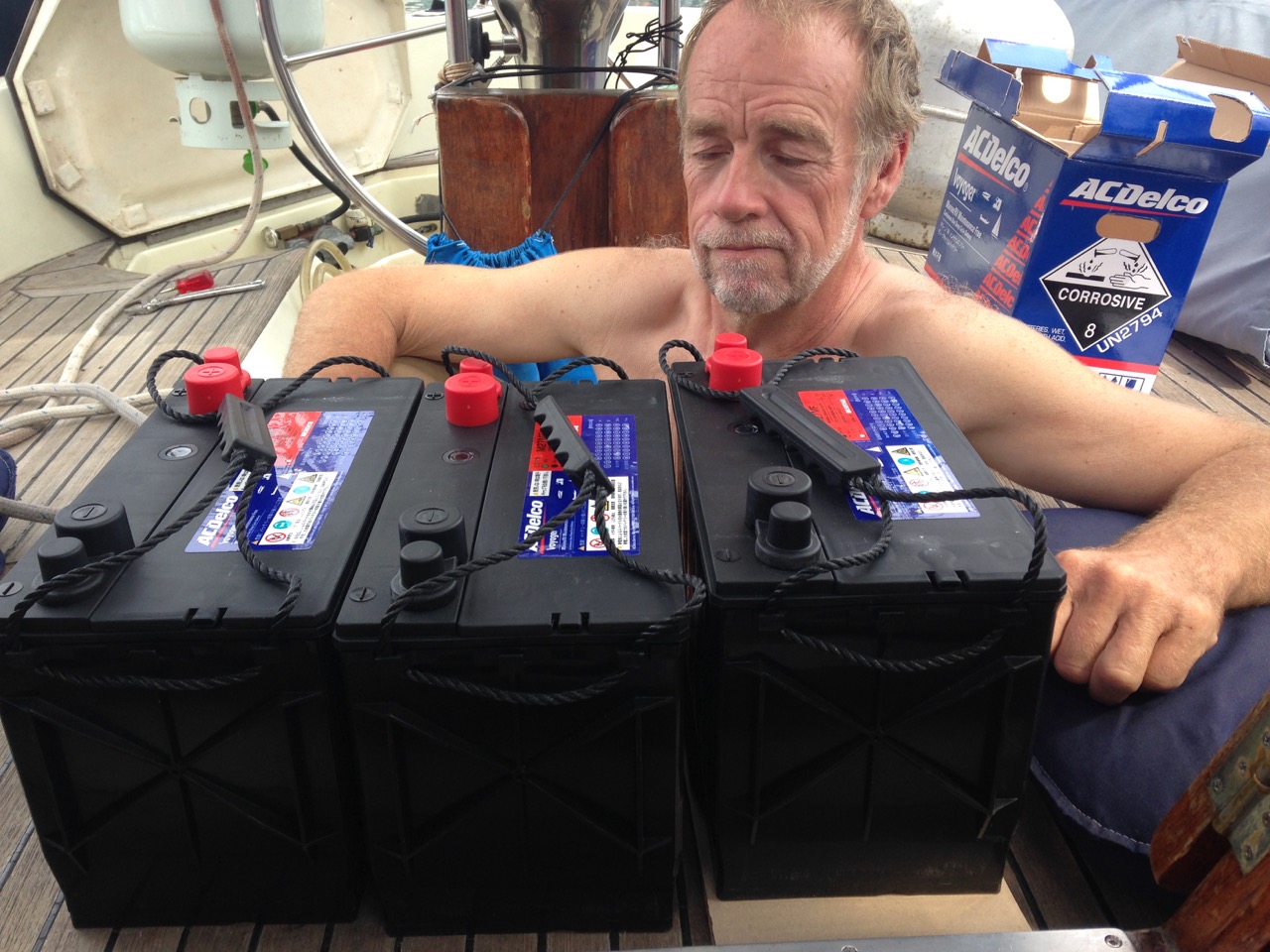

While here I managed to get a few more batteries from amazon, they had a limit of 3, and I needed 5, now we have 5 new batteries, and from the pic below it looks like I’m praying, probably that I get more than 3 years out of this batch.

I had actually decided to go for Lithium Ion batteries, but they aren’t available here, so I worked out that these 5 batteries came in at about £450, and if I get a couple of years out of them, hopefully technology will have moved on in those two years and I will be able to save that much on the Lithium Ion batteries. At least we have power for the passage and don’t need to worry about that.

I have started an inspection of the boat now, working from the tip of the bowsprit to the back of the monitor wind steering checking everything, looking for frayed ropes, split wire, loose bolts or anything that might not be 100%. It didn’t take long to find that the block (pulley) that feeds the furling line onto the staysail drum had split and I only had half of the sheave, which itself had sharp edges and a chunk missing. That explains why I was finding the furling to be stiffer than normal recently. Soon I will climb the mast and do the same checks there.

On the way here I ran the watermaker, however it didn’t live up to its name, as it wouldn’t make water, it seemed to have trouble drawing sea water from the hull fitting, but when I put the maker into bypass mode it drew the water, then switching back to normal mode it continued and we made 20 litres of good water in a couple of hours, so that’s good. We also managed to decant some propane gas into the spare cylinder from Ken, our neighbour in Onomichi last week. so we have gas. We have bought a small portable stove and a dozen butane cylinders, as a backup.

So with gas, water, electric and a much improved engine all fixed, the main concerns are gone. I’m also focussing on the human side of things, like warm clothing, bags of chocolate bars etc 😉 and brushing up on my basic weather forecasting skills.

We have found a massive supermarket just a short ride from here, next to the two massive DIY / Hardware stores, so we will provision fully here, tomorrow I go to the Apple store in Osaka to see about a new display for the iPad (Main Nav device at the helm) as I dropped it the other night, and new batteries for my MacBook, which can’t hold a charge for more than an hour now.

If all goes to plan, we will be ready to leave for the big passage in about 5 days time, so then it’s just a case of working our way east, stopping along the way if the weather changes, then off.

Paul Collister.

So these are AGM batteries? Were the older ones wet cells? If so you should be able to run them down a bit more.

No, these are sealed lead acid, SLA just like the last ones, but from a more reputable source. I would like to think I could get more than 1000 cycles from these, where a cycle would be a discharge to no more than 50%.

I have a lot of theories about why the last ones failed, and I thought about doing an autopsy to find out, I think the plates collapsed and shorted, as each battery lost a cell in turn, once the cell shorted it wanted to go into thermal fun away as it was in parallel with several hundred AH of batteries pumping current into it . However Japan is not the place to create a mess as there is no way to dispose of it.

Roll on battery technology.

How about dietary provisions? It’s a long passage. Need a healthy balanced diet

Good catch on the split sheave. I remember walking our boat bow to stem every day looking for impending failure!

Kathy is on the case. As a vegan she has an even bigger challenge, for me the main problem will be deciding on whether to go for the freshly caught tuna, or the salmon each day ? ?

Ah, the excitement of an imminent departure!